Introduction

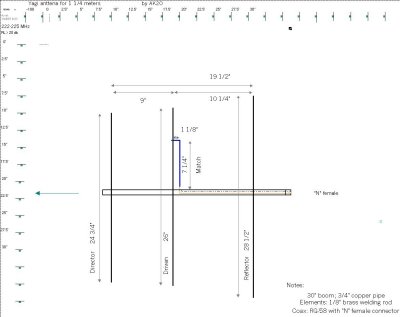

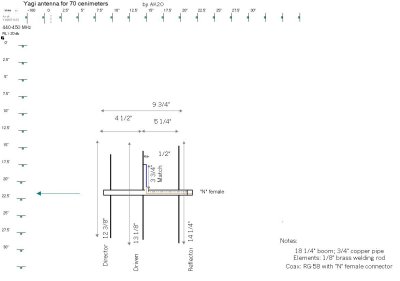

This was a design started about 20 years ago. It's a three-element yagi beam with a gamma match. The match (change from original) now is (DC) directly coupled to the driven element. This helps dissipate static. This original design uses brass welding rods for the elements. This light duty version is the easiest to build and fine for in-town sites.

These drawings show all the dimension you'll need to know to built one for either band. Either print out the image (click to enlarge). The original file is available upon request with a modest donation as well.

This is what it will look like (during construction)

Here's your shopping list for items to pick up at the local hardware store:

Start with marking and drilling the holes for the boom. It this case batches of four antennas were being made. Because of a standard copper stick is 10 feet, four 30" booms work out great.(30" x 4 = 120" = 10') Next, cut the brass rods to length and solder them in place. Remember to center the elements across the center of the boom. For the match; use a DC gamma; take some of the cut shorter lengths of brass rod and solder a 90° bend for the match that goes into the driven element. Use some of that (stripped) wire to wrap the joint (for better strength) and solder the whole glob. The right picture shows a close up of the bend.

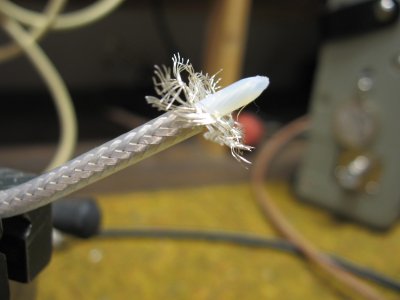

Then drill a 1/4" hole just under or slightly to the side of the end of the match. Next prep the connector and coax by soldering one end to the chassis connector and leave the other end open. Then make a "hook" for this end so you can push the coax inside the boom and coax to out the end out through that hole you drilled.

Probably some tweezers or small needle nose might help pull the end out.

Then dress and solder the coax center to the matching end and the shield to the boom's surface. Even though the picture shows teflon coax, any RG-58/U will be fine. Use the non-foam to avoid melting the dialectic. This is a tricky task the first time around. If you need more details or get to using larger coax (RG-X, etc.) click here for a lot more pictures.

Then you can seal this area with epoxy and/or RTV. Use the non-corrosive RTV. Dow Corning make a good one, called "748" RTV. For information on this product click Here for the PDF file. (right click and "save as"). Also, just discovered is a more "electronics friendly" version is the " 738 " type. Either type probably will work fine.

If you have trouble finding a tube you might try these distributors including some around the Spokane area.

The return loss should be more than 20db. Front to back should be better than 20 db as well. The right picture shows several being built in a production way. Also, note in this picture bending the gamma ended up breaking the rod, so that was soldered (with the wire wrap) as well as the first joint to attach to the driven element.

Here's a typical installation on the tower

Other notes:

The light duty version has been built and tested on both bands and works fine. The materials will weather fine. Present yagis have lasted more that 20 years outside. If you feel compelled to paint, be sure it's not a metallic base (some oil paints) for obvious reason.

![[SRG home Direction]](images/srghome.gif)